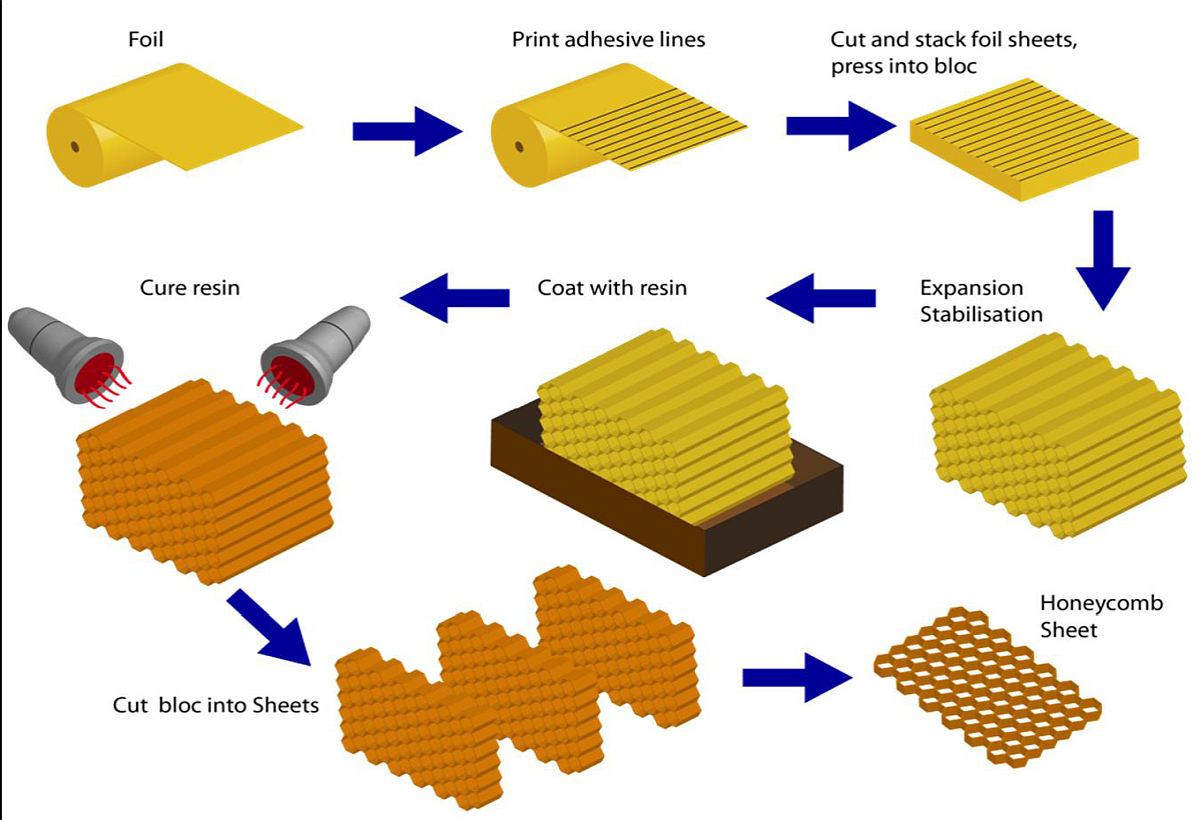

The production process of aluminum honeycomb core

The production process of aluminum honeycomb core generally includes the following steps:Firstly, high-quality aluminum alloy is selected as the raw material. This alloy has good mechanical properties to ensure the strength and durability of the honeycomb core.Secondly, the selected aluminum alloy is processed into thin sheets through rolling or extrusion.Next, a special adhesive is applied to the surface of the aluminum sheet to facilitate the bonding between the sheets.Then, the aluminum sheets are cut into specific sizes and shapes according to the required specifications.After that, the cut aluminum sheets are stacked and bonded together to form a hexagonal structure. This structure gives the aluminum honeycomb core its unique properties, such as light weight and high strength.In the next step, the bonded structure is subjected to a heating process to solidify the adhesive and enhance the bond strength between the sheets.Finally, the finished aluminum honeycomb core undergoes quality inspection to ensure it meets the required standards and specifications.The resulting aluminum honeycomb core has wide applications in various industries due to its excellent properties. It offers advantages such as light weight, high strength, good thermal insulation, and sound insulation.