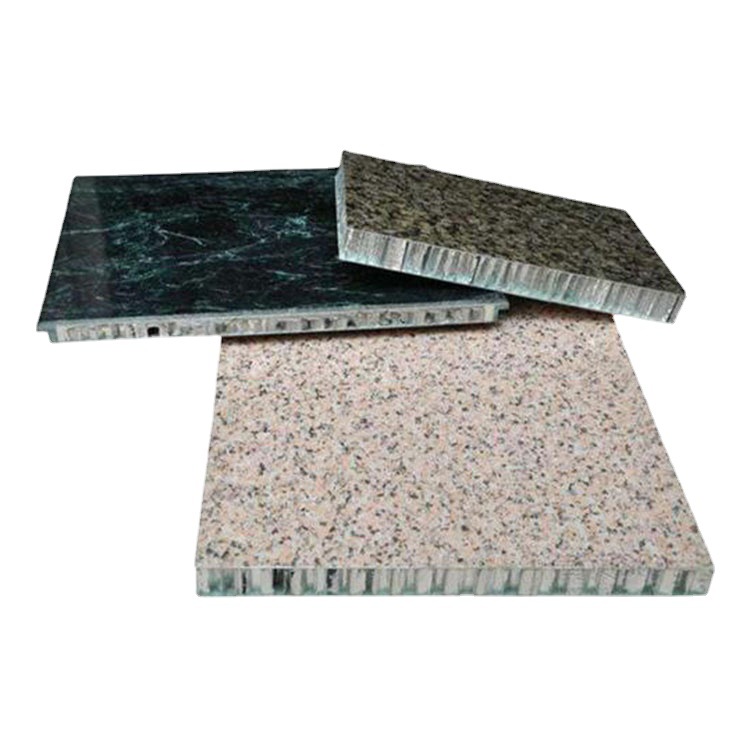

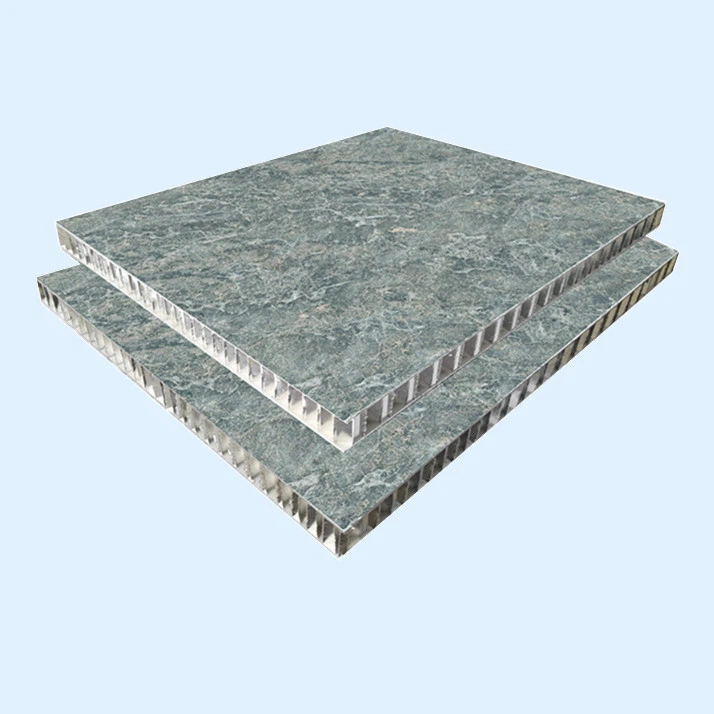

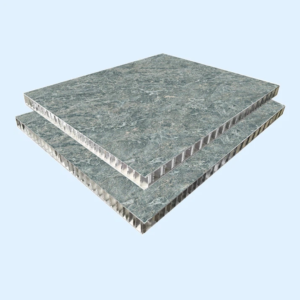

Stone Pattern Aluminum Honeycomb Panel

Material: Aluminum

Size: 1220*2440mm and 1220*2750mm or as customized.

Total thickness: 10mm~30mm or as customized

Surface Treatment: Anodized, Brushed, Foil Decoration, Mirror, Printing, PVDF Coated.

The characteristics and advantages of imitation marble-patterned aluminum honeycomb panels are as follows:

Aesthetic appearance: It has a realistic marble pattern, which can provide an elegant and stylish appearance and add to the decorative effect.

Light weight and high strength: The aluminum honeycomb panel structure is lightweight, but it also has high strength and rigidity, and is not easily deformed.

Good durability: This type of panel is corrosion-resistant and wear-resistant, and can maintain a good appearance and performance for a long time.

Good insulation and heat preservation: The honeycomb structure has good insulation performance, which can improve the insulation effect of the panel and is energy-saving and environmentally friendly.

Fireproof performance: Generally speaking, it has good fireproof performance and meets the requirements of fire safety.

Convenient installation: The installation of imitation marble-patterned aluminum honeycomb panels is relatively simple, which can reduce construction time and cost.

Machinability: The panel can be cut, bent, drilled, and other processing to meet different design needs.

Environmentally friendly and recyclable: Aluminum materials can be recycled, which is environmentally friendly.These features make the imitation marble-patterned aluminum honeycomb panel widely used in the fields of architectural decoration, curtain walls, billboards, furniture, etc. The specific characteristics and advantages may vary depending on the manufacturing process and quality of the product. When selecting and using it, it is recommended to refer to the product specifications and relevant standards.

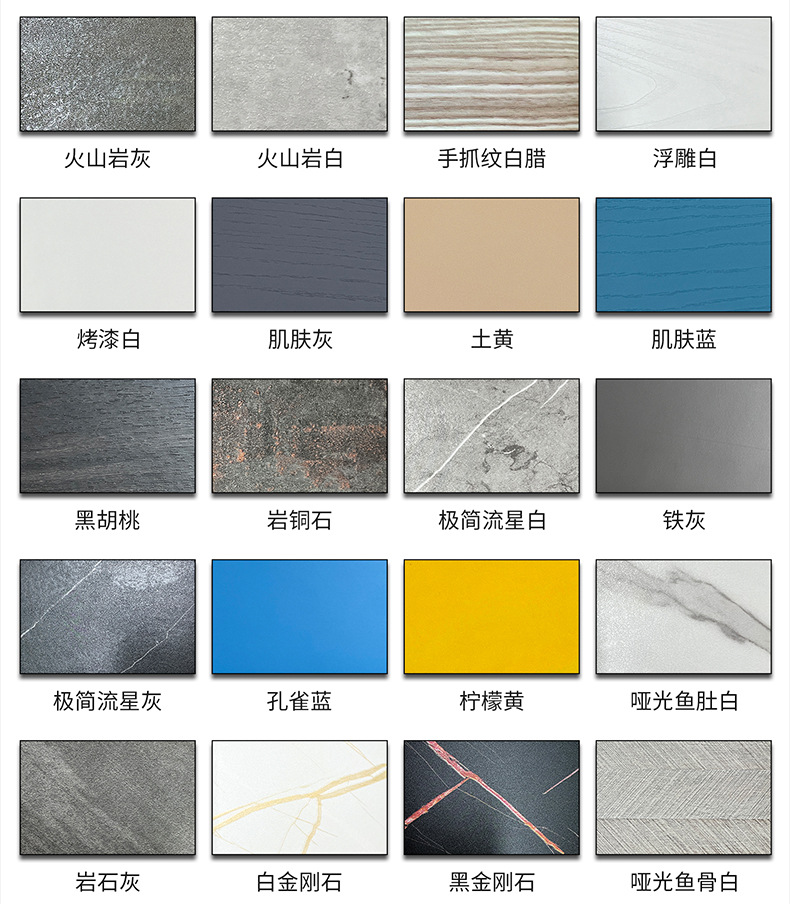

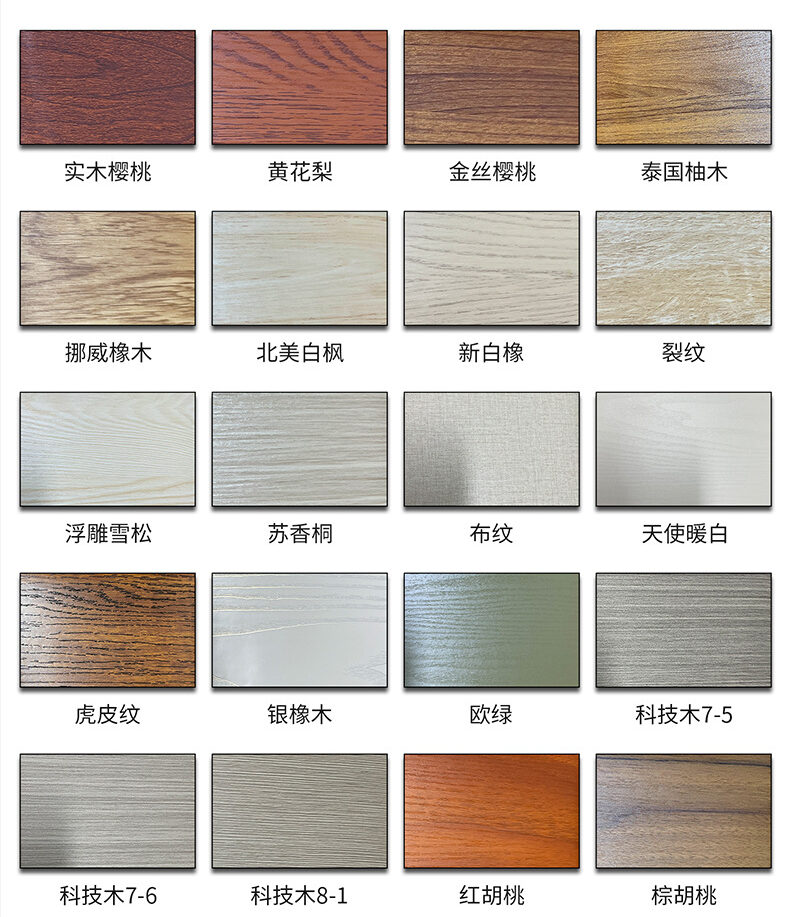

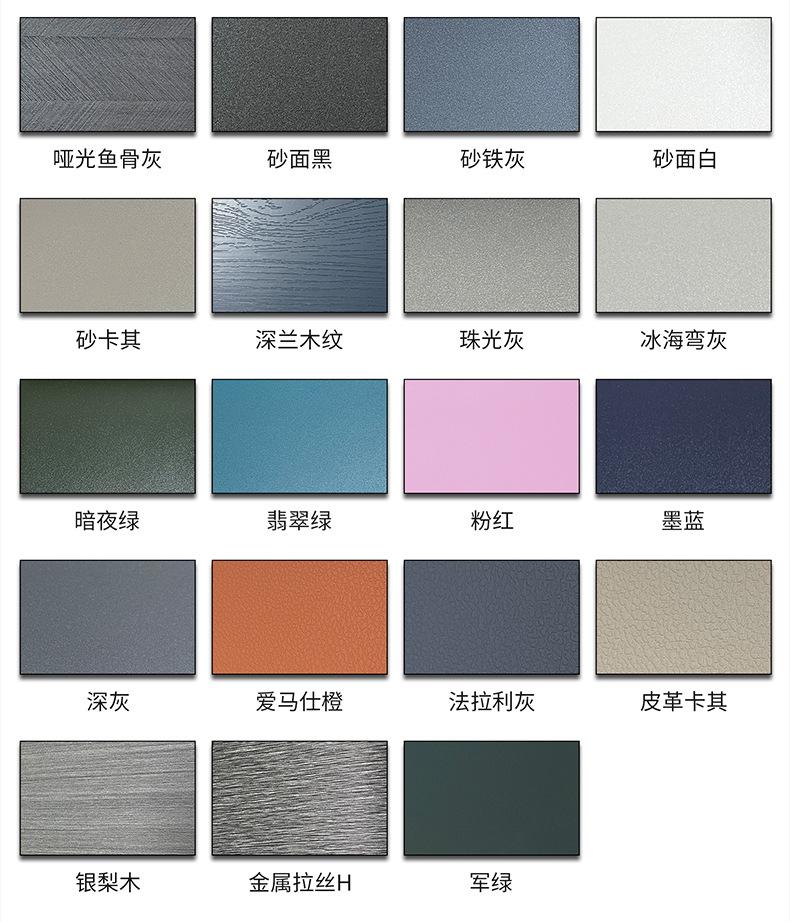

Other Available Colors Avaialble:

PE colors:

PVDF colors:

Stone colors:

Wooden Colors:

Special colors:

FAQ about the aluminum honeycomb panel

1.1 The material:

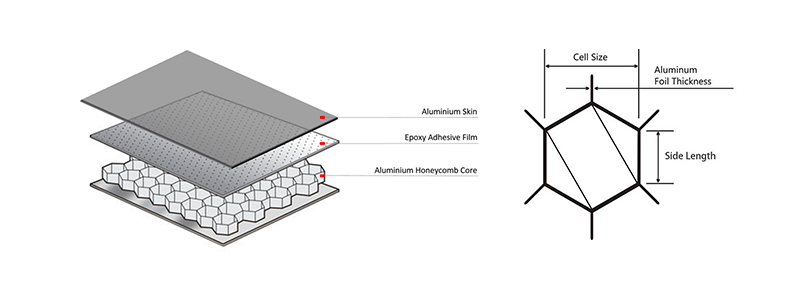

The aluminum honeycomb panel is a honeycomb sandwich panel with a honeycomb structure as its core. It’s inspired by natural hexagonal honeycombs.The unique honeycomb structure makes it lighter than other materials in the same volume and has excellent stiffness and overall stability.Aluminum alloys are neither radioactive nor volatile. They can be fully recycled, saving resources and energy, and minimizing environmental pollution. This makes the honeycomb aluminum plate a new type of energy-saving, environmentally friendly and healthy material.

1.2 The advantage:

Lightweight

These composite panels are prized for their extremely low weight, without compromising on strength. Although they are not as lightweight as some materials, the honeycomb structure means that in certain applications, these panels are up to 40 times stronger.

Rigidity

Despite being low in weight, the material used to create the panel core, and the design of the honeycomb structure ensures that these panels are extremely rigid.

The high strength to weight ratio is among the highest of all honeycomb composite panels which are currently available. The material’s properties and connectivity of the cells provide increased stability and rigidity makes these honeycomb panels ideal for many, high specification industries.

Thermal efficiency

The thermal efficiency of aluminium honeycomb panels makes them highly resistant to temperature fluctuations. Although the aluminium material offers no heat insulation, the hexagonal cellular structure creates a series of closed spaces with air layers between the skins. This prevents airflow and makes it difficult for heat to effectively transmit and convert throughout the panel.

Corrosion resistant

Larcore Aluminium honeycomb panel cores are moisture-resistant, which provides these panels with highly corrosion-resistant properties. The panels also benefit from being resistant to mould and fungal growth within enclosed spaces.

Sound insulation

Larcore Aluminium honeycomb sandwich panels are prized for their sound absorption and sound transmission loss. The aluminium honeycomb core acts as an effective barrier, which prevents sound from being transmitted, whilst also absorbing the sound by reducing the reflection of sound around a room. Despite aluminium having no sound insulation properties, the actual core cell design ensures these panels offer effective sound insulation performance.

Variety of thicknesses

The cell size, thickness and weight ratio are easy to control, so panels are available in a variety of dimensions and configurations. Whether you are looking to increase strength or improve flexibility, there are panel thicknesses available for your requirements.

Fire resistance

The aluminum thin plate and aluminum honeycomb core plate of honeycomb aluminum plate are non flammable materials themselves, and will not produce a melting point even at high temperatures. The melting point of aluminum sheet can reach up to 660 ℃, while the melting point of aluminum honeycomb core plate can reach around 580 ℃. At the same time, aluminum materials themselves have good thermal conductivity and heat dissipation performance, which can quickly dissipate heat and reduce the possibility of fire.Our aluminum honeycomb panels are A2 fire rated in accordance with EN 13501-1:2007 A2-s1,d0.

A2-Non-combustible

s1- No smoke

d0-No flammable dropping

1.3 How to make:

Corex aluminium honeycomb manufacturing begins life as a roll of foil .

Foil is passed through a printer for adhesive lines to be printed.

Once the lines are printed, the foil is cut to size and stacked into piles using our stacking machine.

These stacked sheets are pressed using a heated press to allow the adhesive to cure and bond the sheets of foil together to form a block of honeycomb.

The block of honeycomb can be cut into slices. The thickness of the slices can be tailored to each customer’s individual requirements.

Finally, the honeycomb is expanded, which completes the manufacturing process.

The honeycomb core can be used sandwiched in-between two aluminium alloy skins to create an aluminium composite panel.

1.4 The Size:

Aluminium honeycomb panels are available cut to a custom size or shape, or in a standard sheet size of 48″ x 96″ and 48″ x 120” in a thickness of 1/2″, 5/8” and 3/4″.

1.5 The Surface finished:

The surface of the aluminum honeycomb panel can be treated with fluorocarbon roll coating,anodized,mirror finish,printing,stone pattern,wood pattern,which depends on the requirement of project.

Reviews

There are no reviews yet.