30mm 20mm mill finished aluminum honeycomb core panel for movable houses artists

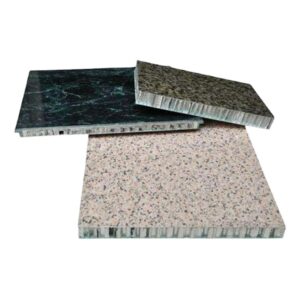

The 30mm/20mm Mill Finished Aluminum Honeycomb Core Panel is an advanced and lightweight composite material specifically designed for movable housing applications and artists. This high-performance panel combines the strength and rigidity of aluminum with the lightweight and insulating properties of honeycomb core, resulting in an exceptional combination of strength and efficiency.

Key Features:

Lightweight: The honeycomb core structure provides a high strength-to-weight ratio, significantly reducing the overall weight of movable houses and facilitating transportation and assembly.

High Strength: The mill finished aluminum faceskins and honeycomb core work together to provide excellent structural integrity, making these panels resistant to bending, buckling, and impact.

Insulating: The honeycomb core acts as a thermal insulator, reducing heat transfer and contributing to improved energy efficiency in movable houses.

Customizable: The panels can be customized to meet specific size, shape, and finish requirements to accommodate diverse architectural designs.

Long-Lasting: Aluminum is highly resistant to corrosion and weathering, ensuring the durability and longevity of these panels in outdoor applications.

Benefits for Movable Houses:

Reduced Weight: Lighter houses are easier to transport and assemble, reducing construction time and labor costs.

Improved Structural Performance: The high strength of the panels ensures reliable structural performance, reducing the risk of damage during transport and relocation.

Energy Efficiency: The insulating properties of the honeycomb core help reduce heating and cooling costs, resulting in lower energy consumption and environmental impact.

Versatile Design Options: Customization options allow for the creation of unique and aesthetically pleasing movable houses that reflect individual artistic visions.

Benefits for Artists:

Lightweight and Portable: These panels are ideal for artists who need to transport their work or create large-scale installations.

Durable and Protective: The panels provide excellent protection for artwork, safeguarding it from damage during transportation and storage.

Versatile and Customizable: The panels can be manipulated and formed into various shapes and sizes, offering unlimited creative possibilities for artists.

Sustainable: Aluminum is a recyclable material, making these panels an environmentally conscious choice for artists concerned about reducing waste.

Applications:

Movable houses and tiny homes

Art installations and sculptures

Exhibit booths and trade show displays

Lightweight roofing and wall systems

Architectural cladding and interior design elements

Packing:

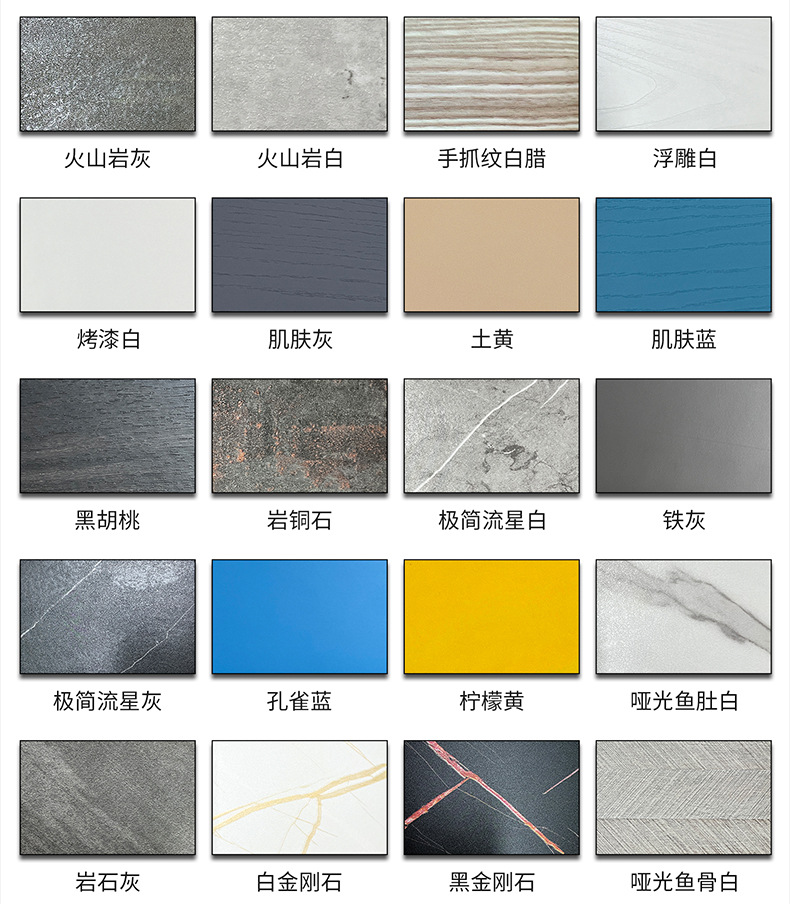

Other Available Colors Avaialble:

PE colors:

PVDF colors:

Stone colors:

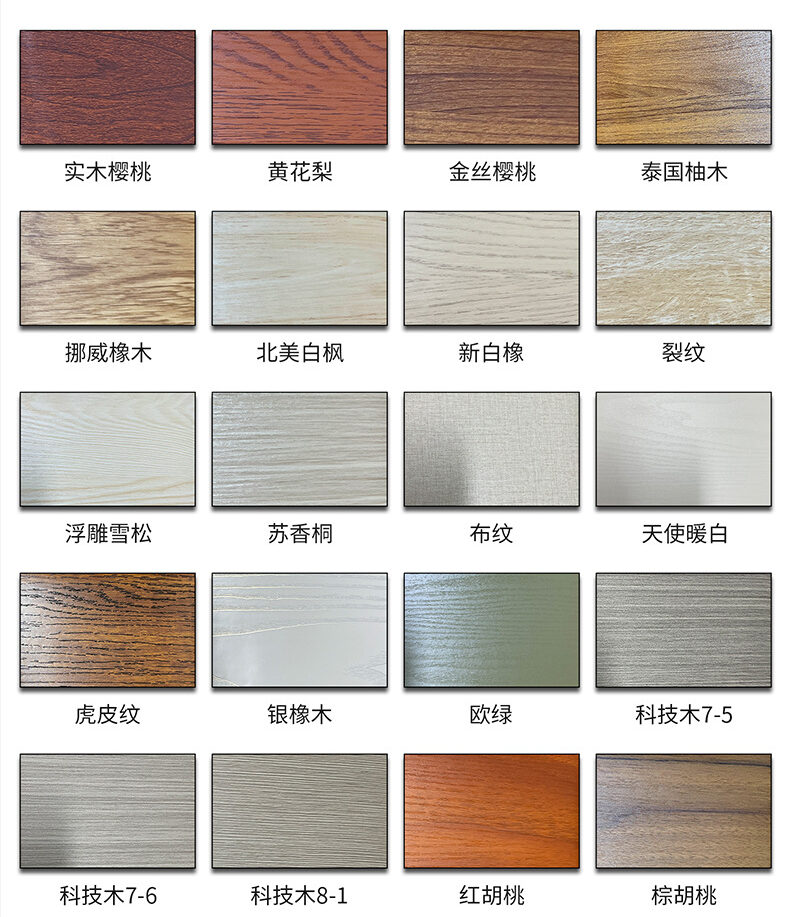

Wooden Colors:

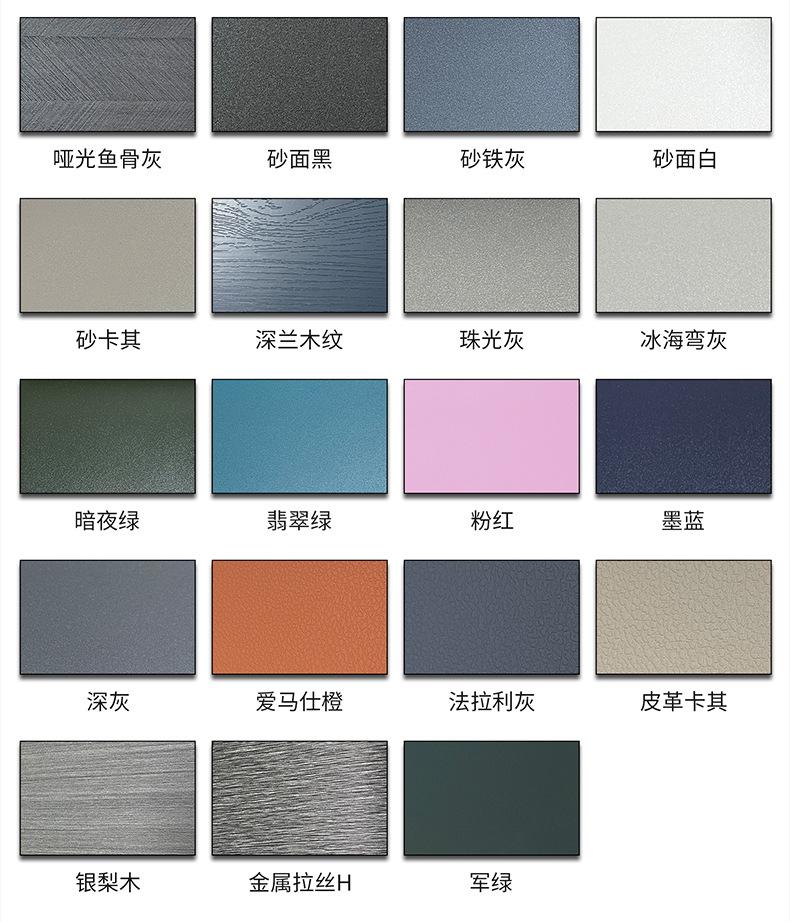

Special colors:

FAQ about the aluminum honeycomb panel

1.1 The material:

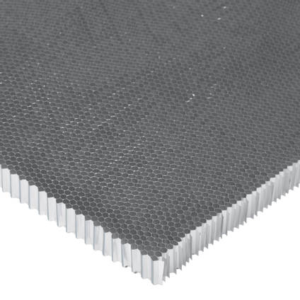

The aluminum honeycomb panel is a honeycomb sandwich panel with a honeycomb structure as its core. It’s inspired by natural hexagonal honeycombs.The unique honeycomb structure makes it lighter than other materials in the same volume and has excellent stiffness and overall stability.Aluminum alloys are neither radioactive nor volatile. They can be fully recycled, saving resources and energy, and minimizing environmental pollution. This makes the honeycomb aluminum plate a new type of energy-saving, environmentally friendly and healthy material.

1.2 The advantage:

Lightweight

These composite panels are prized for their extremely low weight, without compromising on strength. Although they are not as lightweight as some materials, the honeycomb structure means that in certain applications, these panels are up to 40 times stronger.

Rigidity

Despite being low in weight, the material used to create the panel core, and the design of the honeycomb structure ensures that these panels are extremely rigid.

The high strength to weight ratio is among the highest of all honeycomb composite panels which are currently available. The material’s properties and connectivity of the cells provide increased stability and rigidity makes these honeycomb panels ideal for many, high specification industries.

Thermal efficiency

The thermal efficiency of aluminium honeycomb panels makes them highly resistant to temperature fluctuations. Although the aluminium material offers no heat insulation, the hexagonal cellular structure creates a series of closed spaces with air layers between the skins. This prevents airflow and makes it difficult for heat to effectively transmit and convert throughout the panel.

Corrosion resistant

Larcore Aluminium honeycomb panel cores are moisture-resistant, which provides these panels with highly corrosion-resistant properties. The panels also benefit from being resistant to mould and fungal growth within enclosed spaces.

Sound insulation

Larcore Aluminium honeycomb sandwich panels are prized for their sound absorption and sound transmission loss. The aluminium honeycomb core acts as an effective barrier, which prevents sound from being transmitted, whilst also absorbing the sound by reducing the reflection of sound around a room. Despite aluminium having no sound insulation properties, the actual core cell design ensures these panels offer effective sound insulation performance.

Variety of thicknesses

The cell size, thickness and weight ratio are easy to control, so panels are available in a variety of dimensions and configurations. Whether you are looking to increase strength or improve flexibility, there are panel thicknesses available for your requirements.

Fire resistance

The aluminum thin plate and aluminum honeycomb core plate of honeycomb aluminum plate are non flammable materials themselves, and will not produce a melting point even at high temperatures. The melting point of aluminum sheet can reach up to 660 ℃, while the melting point of aluminum honeycomb core plate can reach around 580 ℃. At the same time, aluminum materials themselves have good thermal conductivity and heat dissipation performance, which can quickly dissipate heat and reduce the possibility of fire.Our aluminum honeycomb panels are A2 fire rated in accordance with EN 13501-1:2007 A2-s1,d0.

A2-Non-combustible

s1- No smoke

d0-No flammable dropping

1.3 How to make:

Corex aluminium honeycomb manufacturing begins life as a roll of foil .

Foil is passed through a printer for adhesive lines to be printed.

Once the lines are printed, the foil is cut to size and stacked into piles using our stacking machine.

These stacked sheets are pressed using a heated press to allow the adhesive to cure and bond the sheets of foil together to form a block of honeycomb.

The block of honeycomb can be cut into slices. The thickness of the slices can be tailored to each customer’s individual requirements.

Finally, the honeycomb is expanded, which completes the manufacturing process.

The honeycomb core can be used sandwiched in-between two aluminium alloy skins to create an aluminium composite panel.

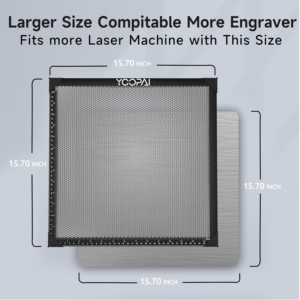

1.4 The Size:

Aluminium honeycomb panels are available cut to a custom size or shape, or in a standard sheet size of 48″ x 96″ and 48″ x 120” in a thickness of 1/2″, 5/8” and 3/4″.

1.5 The Surface finished:

The surface of the aluminum honeycomb panel can be treated with fluorocarbon roll coating,anodized,mirror finish,printing,stone pattern,wood pattern,which depends on the requirement of project.

Reviews

There are no reviews yet.