FAQ for purchasing aluminum honey plate

1. How to purchase aluminum alloy honeycomb plates?

The decorative surface of aluminum alloy honeycomb plate should have a neat appearance, with straight and neat cut edges without burrs, no exposed aluminum honeycomb core on the front and back sides, and no obvious cracks at the folded edges; Non decorative surfaces are required to have no damage that affects the use of the product, and the product is not degummed.

2. How to calculate the weight of aluminum honeycomb plate?

Dimensions of aluminum alloy honeycomb plates: length, width, and thickness of the plates.

Density of aluminum alloy: the density of aluminum is usually around 2.7 grams per cubic centimeter.

The type of honeycomb structure: different types of honeycomb structures have different density and strength characteristics. A honeycomb structure with lower density will result in lighter plates.

Weight calculation of aluminum alloy honeycomb panel:

Weight (kg)=Area (square meters) x Thickness (meters) x Density (kg/cubic meter)

Please note that this calculation method is an approximation as it does not take into account the effects of plate edges, borders, connections, and other complex structures. In practical applications, manufacturers usually provide detailed information about the weight of their products in order to estimate them more accurately.

3. Aluminum honeycomb plate or Aluminum-plastic composite plate, which is better?

In the construction or curtain wall industry, there are two popular types of composite panels: aluminum honeycomb plates and aluminum plastic composite panels. The two types of plates are similar on the surface, but the internal components of the two materials are different. Understanding the differences can help you make wise choices when making a purchase.

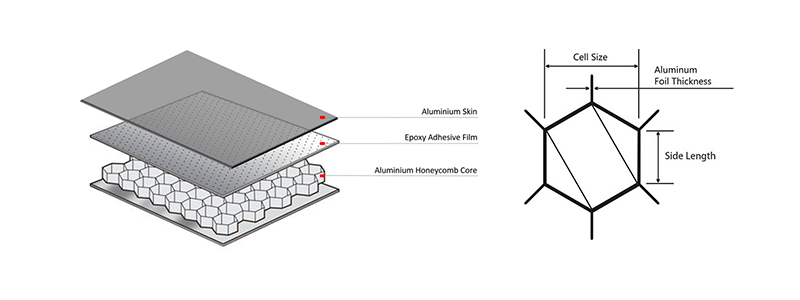

Aluminum honeycomb plate: it is a sandwich plate with a structural design where the upper and lower aluminum panels are attached to the aluminum honeycomb core. Equipped with polyester or fluorocarbon coating. The honeycomb board adopts a lighter honeycomb core layer than the plastic core, with a thickness of 12mm and 25mm. Due to its stable structure and low density, aluminum honeycomb plates are widely used in rocket fairings, automotive skins and doors, train bulkheads, building curtain walls, etc.

Aluminum plastic plate: like aluminum honeycomb plate, it is also a sandwich plate. It is formed by pressing two thin aluminum alloys and thermoplastic core materials, forming a sandwich shape. Aluminum plastic plates are made of plastic with a layer of PE or LDPE, with a thickness of 3mm to 8mm. Aluminum composite panels are commonly used for wall cladding, signage, and exterior walls. At present, the use of aluminum plastic panels has also been incorporated into the furniture industry, as they bond well with plywood or wood, giving kitchen or bathroom cabinets a gorgeous appearance.

4. Inventory dimensions and tolerance table for aluminum alloy honeycomb plates

Aluminum alloy honeycomb core is usually a hexagonal structure with a side length of 10mm or less.

Aluminum honeycomb core with a side length of less than or equal to 6mm, with an aluminum foil thickness of no less than 0.05mm;

The aluminum honeycomb core with a side length of 6 mm to 10 mm shall have an aluminum foil thickness of not less than 0.07 mm.

We can provide you the most comprehensive inventory of aluminum products and can also supply you comtomized products. Precise quotation will be privided within 24 hours.Get a quote.